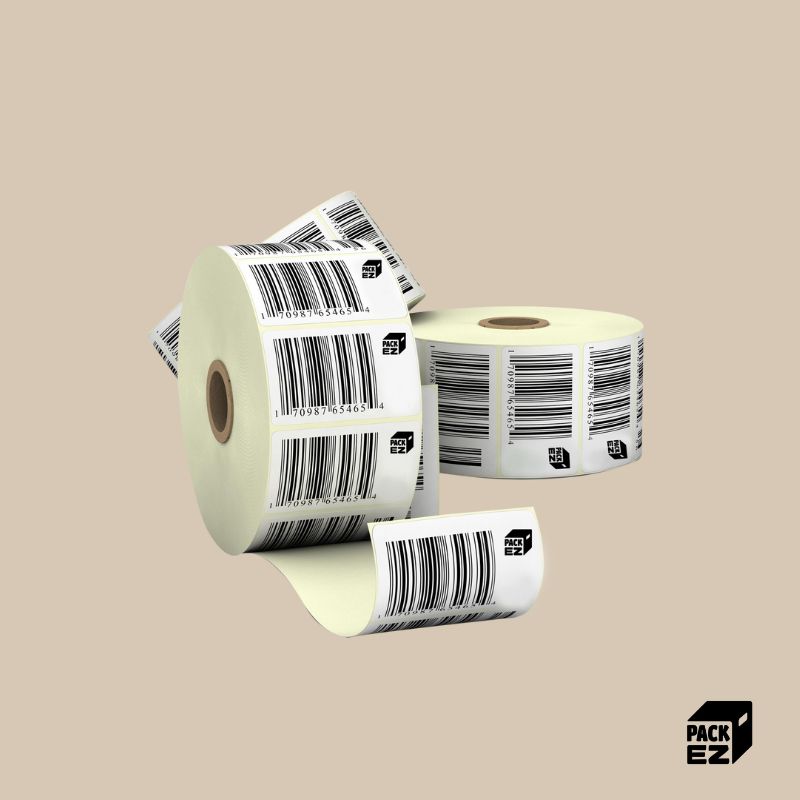

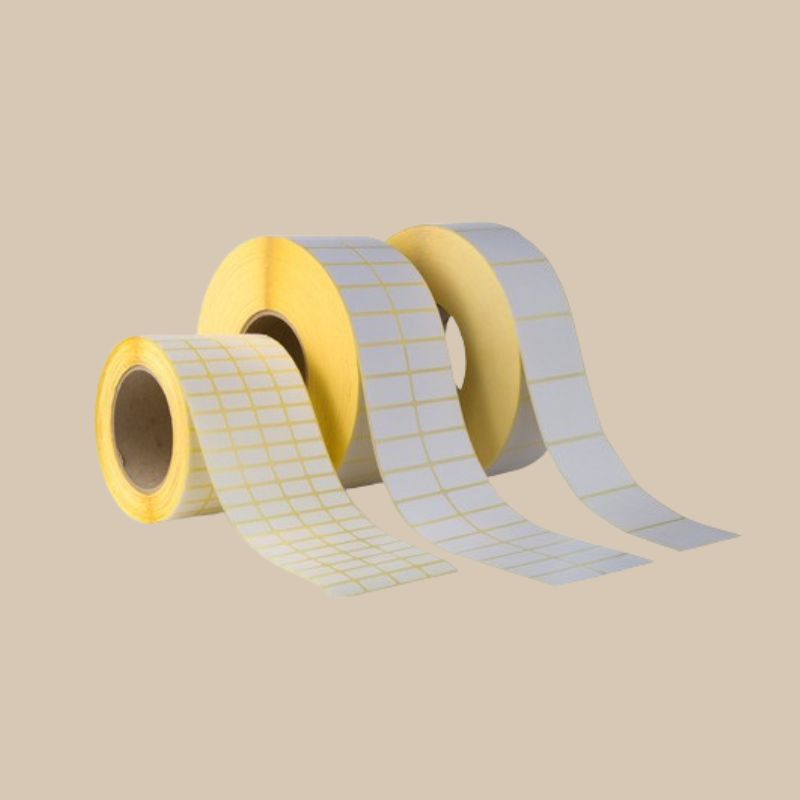

Use cases for plain white barcode labels include:

- Product Labeling: Manufacturers often use plain white barcode labels to create product labels with unique identification codes for inventory and tracking purposes.

- Retail: In retail settings, these labels are commonly used for pricing and inventory management. Retailers can print their own barcodes and pricing information on these labels.

- Warehousing: Plain white barcode labels are ideal for creating labels for inventory storage, helping to manage and track stock in warehouses efficiently.

- Asset Tracking: Businesses use plain white barcode labels for asset tracking by printing unique identifiers that can be scanned during regular audits or maintenance checks.

- Shipping and Logistics: These labels can be employed for creating shipping labels with barcode information for accurate and efficient handling in logistics processes.

By opting for plain white barcode labels, businesses can maintain a clean and professional look while having the flexibility to print variable information as needed for specific applications.

There are mainly three types of ribbons used in thermal transfer printing:

- Wax Ribbons: Suitable for printing on paper labels, wax ribbons are cost-effective and offer good print quality. However, they may not be as durable as other types.

- Resin Ribbons: Resin ribbons are designed for printing on synthetic materials, providing durable and long-lasting prints. They are resistant to various environmental conditions, making them ideal for applications where labels may be exposed to harsh elements.

- Wax/Resin Ribbons: Combining elements of both wax and resin, these ribbons offer a balance between durability and cost. They are suitable for printing on a variety of label materials and are often used in applications with moderate environmental challenges.

The choice between these types depends on factors like the specific label material, required durability, and the environmental conditions the labels will face.